Casestudie: CFD Simulatie van de uitlaat van een onderwater jacht

met Simcenter STAR-CCM+

met Simcenter STAR-CCM+

Om een gestroomlijnd jachtuiterlijk en minder uitlaatlawaai te garanderen, worden brandstofuitlaten gewoonlijk onder de waterlijn geplaatst. Over de uitlaat wordt dan een scoop geplaatst om de waterdruk en de distributie van uitlaatgassen en koelwater te regelen. Hoe gaan ingenieurs te werk bij het beoordelen en optimaliseren van deze scoop-ontwerpen?

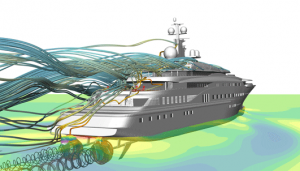

Bij Femto Engineering maken we gebruik van geavanceerde modelleringsmethoden om de effecten van verschillende stromingsparameters op een ontwerp te evalueren. Onze expertise ligt in uitgebreide stromingsmodellering in combinatie met beweging en structurele componenten. Het proces van het gebruik van Computation Fluid Dynamics (CFD) om de prestaties van dit soort ontwerpen te voorspellen is niet eenvoudig, maar brengt grote waarde in termen van meer inzicht, minder onzekerheid, en een verminderde behoefte aan uitgebreide fysieke testen. Zodra een model is opgezet, kunnen ingenieurs een veelheid aan ontwerpscenario’s testen, wat resulteert in ontwerpen van hogere kwaliteit. In deze casestudy leest u meer over zo’n modelopstelling voor een uitlaat van een jacht onder de waterlijn.

Bij Femto Engineering maken we gebruik van geavanceerde modelleringsmethoden om de effecten van verschillende stromingsparameters op een ontwerp te evalueren. Onze expertise ligt in uitgebreide stromingsmodellering in combinatie met beweging en structurele componenten. Het proces van het gebruik van Computation Fluid Dynamics (CFD) om de prestaties van dit soort ontwerpen te voorspellen is niet eenvoudig, maar brengt grote waarde in termen van meer inzicht, minder onzekerheid, en een verminderde behoefte aan uitgebreide fysieke testen. Zodra een model is opgezet, kunnen ingenieurs een veelheid aan ontwerpscenario’s testen, wat resulteert in ontwerpen van hogere kwaliteit. In deze casestudy leest u meer over zo’n modelopstelling voor een uitlaat van een jacht onder de waterlijn.

De missie die we willen volbrengen is tweeledig. Ten eerste willen wij een basismodel hebben waarop verschillende schepontwerpen kunnen worden getest. Hiervoor moeten we een model ontwikkelen dat bestaat uit heet uitlaatgas, koelwater, een uitlaatsysteem, het wateroppervlak, en een bewegende boot. Hoe meer je deze factoren in samenhang bestudeert, hoe nauwkeuriger je simulatie zal zijn.

Zoals eerder gezegd, kan het opzetten van zo’n studie moeilijk zijn en vereist het geavanceerde vaardigheden en hulpmiddelen. Daarom was deel twee van onze missie om de mogelijkheden van Simcenter STAR-CCM+ voor dit soort processen te demonstreren. Simcenter STAR-CCM+ is Siemens vlaggenschip CFD software, waarvan wij zowel gebruiker als distributeur zijn. Simulaties die we bij Femto Engineering doen met multi-fysica en complexe geometrieën worden meestal gedaan met Simcenter STAR-CCM+.

Zoals eerder gezegd, kan het opzetten van zo’n studie moeilijk zijn en vereist het geavanceerde vaardigheden en hulpmiddelen. Daarom was deel twee van onze missie om de mogelijkheden van Simcenter STAR-CCM+ voor dit soort processen te demonstreren. Simcenter STAR-CCM+ is Siemens vlaggenschip CFD software, waarvan wij zowel gebruiker als distributeur zijn. Simulaties die we bij Femto Engineering doen met multi-fysica en complexe geometrieën worden meestal gedaan met Simcenter STAR-CCM+.

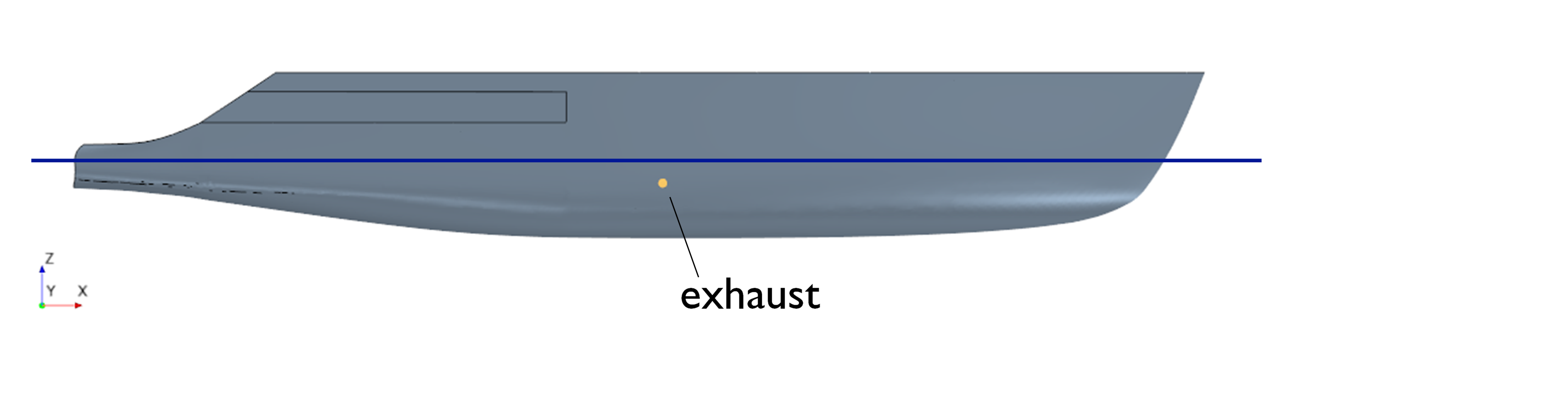

In deze CFD simulatie is geen scoop of kap toegevoegd aan de uitlaat van het onderwater jacht. Op deze manier kunnen we het gedrag van uitlaatgassen die onopvallend de uitlaat verlaten en de gevolgen voor de vervuiling van de romp beoordelen. Dit stelt ons in staat een basismodel te maken waarin op een later tijdstip een verscheidenheid aan schepontwerpen kan worden ingepast en virtueel getest.

Onze studie maakt gebruik van een meerfasestroom voor een generiek vereenvoudigd jacht. Omwille van de eenvoud zijn de bovendekken niet opgenomen.

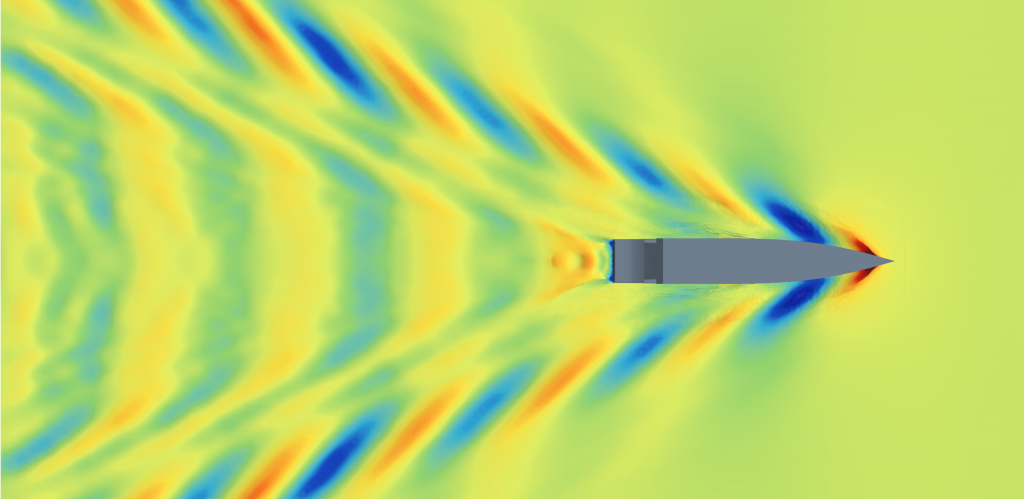

Het jacht in onze studie vaart met een snelheid van ongeveer 14 knopen (7,1 m/s). De uitlaat bevindt zich op de romp ongeveer 1 meter onder de waterlijn van het schip en heeft een diameter van 0,5 meter. De massastroom bedraagt 10,5 kg/s en de temperatuur van het gas bedraagt 60 °C. De volumestroom van het uitlaatgas bedraagt ongeveer 0,5% van de totale volumestroom. Met simulatie kan elk van de bovenstaande getallen gemakkelijk worden aangepast aan andere mogelijke scenario’s.

Voor de transiënte CFD-simulatie wordt een Volume of Fluid (VOF)-methode gebruikt, met twee fasen: water en lucht. Het water wordt gemodelleerd als constante dichtheid, terwijl de lucht wordt gemodelleerd als een gas met meerdere componenten, met omgevingslucht en uitlaatgaslucht als componenten, om onderscheid te kunnen maken. Het ideale gasmodel wordt gebruikt omdat temperatuureffecten aanwezig zijn.

Het gedrag van de uitlaatgassen die de uitlaat verlaten wordt getoond in de animatie. rechtsboven in de animatie wordt de hoeveelheid uitlaatgassen getoond die langs de romp stroomt.

De CFD-simulatie laat zien hoe de uitlaatgassen uit het water opstijgen en boven het wateroppervlak op de bewegende romp terechtkomen, wat duidelijk aantoont hoe ver ze kunnen opstijgen.

Heeft u vragen of interesse in één van onze diensten? Neem dan vrijblijvend contact met ons op. Wij helpen u graag.

Bij Femto Engineering helpen we bedrijven hun innovatieve ambities te bereiken met specialistische engineering consultancy, software en R&D.

Wij zijn Siemens DISW Expert Partner voor Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ en SDC Verifier. Neem contact met ons op en laat FEM en CFD voor u werken.

Schrijf je nu in voor onze nieuwsbrief en ontvang maandelijks FEA kennis, nieuws en tips gratis in je inbox.