Korte inleiding over topologie optimalisatie

In dit artikel delen wij onze inzichten over hoe nieuwe ontwerprichtingen te genereren met behulp van topologie-optimalisatie.

In dit artikel delen wij onze inzichten over hoe nieuwe ontwerprichtingen te genereren met behulp van topologie-optimalisatie.

In tegenstelling tot maat- en vormoptimalisatie kunnen structuren die door topologie-optimalisatie zijn geoptimaliseerd, elke vorm binnen de ontwerpruimte bereiken. Als we bijvoorbeeld onderdelen nemen die door middel van Additive Manufacturing worden geproduceerd, zijn de mogelijkheden bijna eindeloos, aangezien Additive Manufacturing geen beperkingen stelt aan de vorm van het onderdeel, de enige beperking bij Additive Manufacturing is de minimale wanddikte.

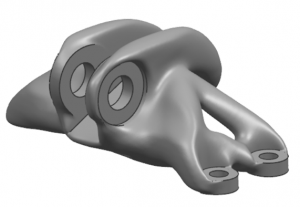

Het optimaliseren van onderdelen door topologie optimalisatie zonder toepassing van productiebeperkingen zal resulteren in organisch uitziende ontwerpen (zie afbeelding links). Dit komt omdat het materiaal de kortste weg zal kiezen van de belasting naar de beperking, wat mathematisch de meest efficiënte vorm oplevert. Organische resultaten geven een goed inzicht in de functionele eisen van het onderdeel.

Wanneer het geoptimaliseerde onderdeel moet worden geproduceerd met conventionele produktiemethoden zoals gieten of frezen, kunnen produktiebeperkingen en/of symmetriepatronen worden toegepast om holten te vermijden en de gewenste condities op te leggen.Topologie-optimalisatie is een belangrijk hulpmiddel bij simulatie-gestuurd ontwerpen.

De eerste stap bij het opzetten van een topologie optimalisatie is de definitie van de ontwerpruimte, dit is het gebied dat door de solver wordt gebruikt voor de optimalisatie. Wanneer de solver een optimalisatie moet uitvoeren verwijdert hij materiaal uit de ontwerpruimte dat niet nodig is, hij kan geen materiaal toevoegen, om deze reden is het belangrijk om een ontwerpruimte toe te wijzen die groot genoeg is zodat de solver materiaal kan blijven verwijderen totdat hij de beste topologie heeft gevonden.

De volgende stap in de optimalisatie-opzet is de toepassing van geometrische beperkingen. Een geometrische beperking legt beperkingen op aan de veranderingen die de oplosser kan maken aan de topologie, dit kan worden geïnterpreteerd als de gebieden die niet mogen veranderen tijdens het optimalisatieproces. In technische termen worden deze gebieden de bevroren gebieden genoemd. Tijdens de optimalisatie zal de solver deze gebieden laten zoals ze zijn terwijl hij omringend materiaal extraheert om de beste topologie te vinden.

Een andere belangrijke stap is het bepalen van de optimalisatiedoelstelling. Deze stap definieert wat we willen bereiken met de optimalisatie. Bij topologie-optimalisaties is het meestal zo dat wij de stijfheid willen maximaliseren en tegelijkertijd het volume van het model willen minimaliseren. De grotere stijfheid wordt bereikt door de vervormingsenergie in het model te minimaliseren. Het is ook mogelijk te optimaliseren naar andere doelstellingen zoals bepaalde Eigenfrequenties of lokale verplaatsingen.

De software die door Femto-ingenieurs wordt gebruikt voor topologie-optimalisaties is Altair Optistruct en Simcenter 3D. Tijdens de eerste fasen van het conceptuele ontwerp kan topologie-optimalisatie met Altair Optistruct waardevolle inzichten en nieuwe ideeën opleveren. De solver optimaliseert voor maximale stijfheid, specifieke vervormingen, Eigen frequenties en vele andere parameters. Dit wordt gedaan door een ontwerpruimte te definiëren waaruit de solver materiaal kan verwijderen tot de meest optimale vorm is bereikt. Altair Optistruct is een gevestigde speler met een lange staat van dienst op het gebied van gebruikersgerichte upgrades, waardoor de software zeer geschikt is voor snelle en eenvoudige topologie-optimalisatie.

Door de kracht van topologie-optimalisatie te gebruiken, waren de Femto-ingenieurs in staat een 20% kostenefficiënter M-Frigates Radar mastontwerp voor DMO te realiseren. U kunt hier meer lezen over de DMO case study. Als u geïnteresseerd bent in onze product optimalisatie diensten of advies nodig heeft over methoden, tools en procedures, dan horen wij graag van u!

Heeft u vragen of interesse in één van onze diensten? Neem dan vrijblijvend contact met ons op. Wij helpen u graag.

Bij Femto Engineering helpen we bedrijven hun innovatieve ambities te bereiken met specialistische engineering consultancy, software en R&D.

Wij zijn Siemens DISW Expert Partner voor Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ en SDC Verifier. Neem contact met ons op en laat FEM en CFD voor u werken.

Schrijf je nu in voor onze nieuwsbrief en ontvang maandelijks FEA kennis, nieuws en tips gratis in je inbox.